English

English

Main Functions and Features of Hydrogen Refueling Dispenser:

The hydrogen refueling dispenser is a fueling device used in hydrogen refueling stations for metering and settlement. It integrates a flow control unit, pressure control unit, metering unit, and automatic control unit. Its main functions include controlling hydrogen refueling pressure, flow, and temperature, as well as managing the first-stage refueling process. The system includes high-pressure pipelines, valves, hydrogen nozzles, metering, and price display.

The dispenser is designed to fill fuel cell vehicles with 35 MPa high-pressure hydrogen.

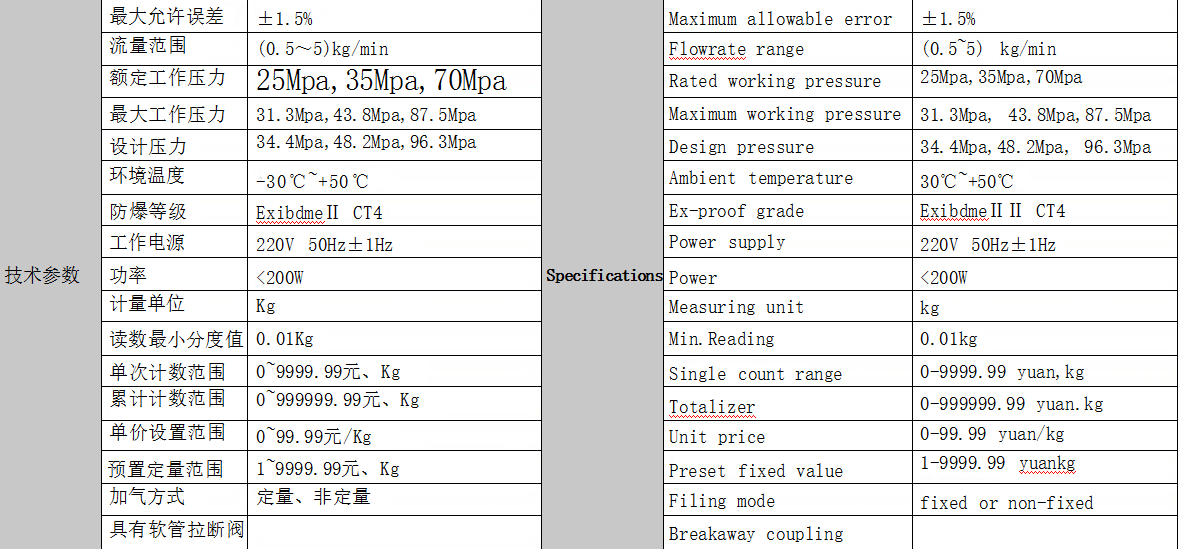

Key process parameters:

Operating pressure: 43.8 MPa

Design pressure: 48.2 MPa

Design flow rate: 0.1–7.2 kg/min

Metering accuracy: ±2.5%

Ambient temperature: -40 to 55 ℃

Hydrogen pipeline material: SS 316L

Valves from brands such as Swagelok, Maximator

Connections use double ferrule and NPT threaded types

Filling interface: TK25/TK16

Box-type structure with high-brightness digital display

Uses Coriolis mass flow meter for measurement

Equipped with a 4-meter high-pressure hose with breakaway valve

High, medium, and low-pressure lines are each equipped with high-precision filters with filtration accuracy ≤5μm.

Highlights of the hydrogen dispenser:

The whole machine is explosion-proof with national-level certification: Exde ia Ga ib mb ⅡC T4 Gb;

The electrical control system is explosion-proof with national certification: Exd[ib] IICT4 Gb;

Rain and dust protection design with IP55 protection level;

Equipped with imported HIP brand flow control valves, fully automatic flow control;

Supports Sinopec card machine linkage and has testing certification;

Data transmission functionality with open communication interfaces and protocols for easy system integration;

Complies with SAE J2601 standard, patented automatic refueling program protection—automatically stops refueling at set pressure 35 MPa, ensuring intrinsic safety;

Fully automatic control of the refueling process with one-button operation;

Equipped with hydrogen leak detection, alarm, and power-off functions;

Standardized dispenser housing supports installation of various models with dual metering, single metering, dual nozzles, or single nozzle configurations;

Three-line intake model features sequential control of refueling, metering, etc., with dispenser automatic control to prevent fueling interruptions due to station PLC communication faults.

Process flow of the hydrogen dispenser:

Hydrogen enters the dispenser: Hydrogen enters the dispenser intake pipeline from the gas source interface, marking the start of the process.

Filtering and metering: Hydrogen passes through a gas filter and a Coriolis mass flow meter in sequence, ensuring gas purity and accurate measurement.

Regulation and heat exchange: Hydrogen is further regulated and optionally preheated via a flow regulator and heat exchanger to improve efficiency.

Filling hydrogen storage tanks: The treated hydrogen is filled into storage tanks through the hydrogen hose and nozzle, completing the refueling process.

Throughout the process, the dispenser control system plays a crucial role by automatically controlling the refueling operation and communicating in real-time with the station control system and communication interfaces, ensuring safety and efficiency.