English

English

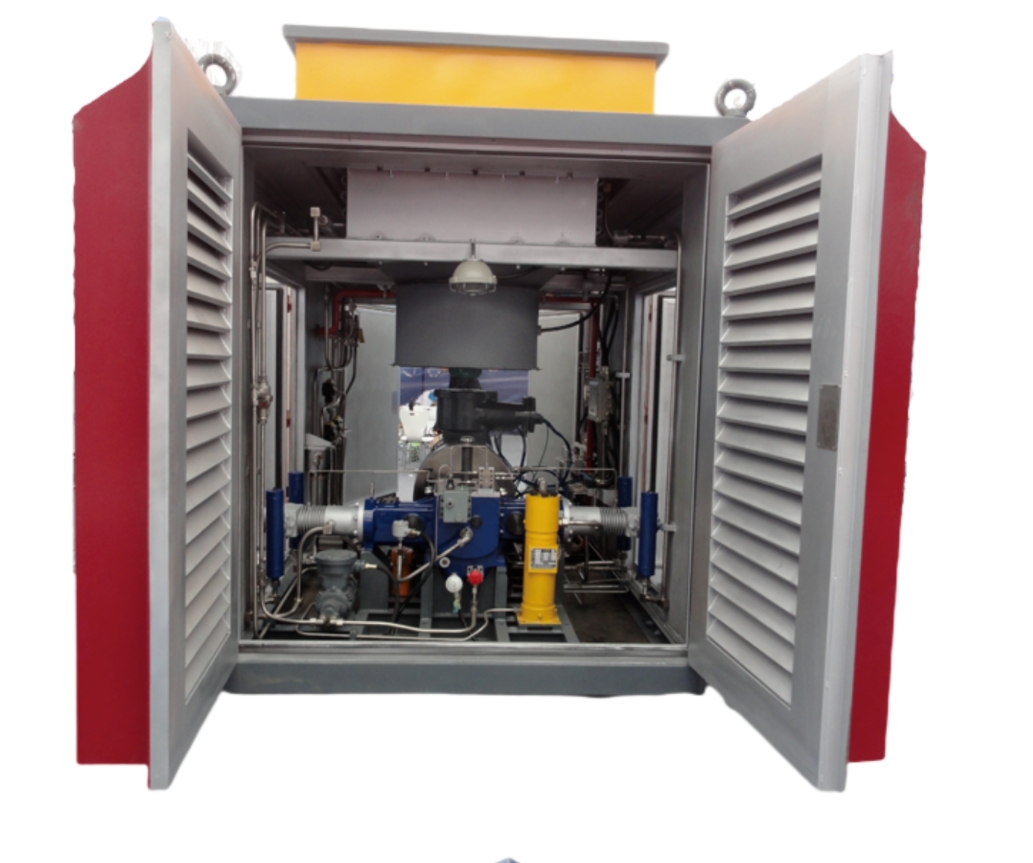

The CNG conventional station compressor adopts a two-column horizontally symmetrical structure, capable of multi-stage compression; the transmission structure uses forced lubrication, and the cylinder adopts a low-oil lubrication method.

CNG skid mounting sub-station compressor drive section adopts two rows of completely horizontal symmetrical structure, cylinder arrangement on both sides, two-stage compression.

The BOG recovery compressor is mainly used for handling low-temperature liquids such as liquefied natural gas (LNG), low-temperature propane, and low-temperature ethane. Generally, it is required to compress the BOG and then condense it back into liquid form, or directly compress and output it.

Natural gas compressors for oil and gas fields are essential equipment used to increase the pressure of produced natural gas for transportation through pipelines or for storage purposes. These compressors play a crucial role in maintaining the flow of natural gas from the wellhead to processing facilities or distribution points.

The BOG recovery compressor is mainly used for handling low-temperature liquids such as liquefied natural gas (LNG), low-temperature propane, and low-temperature ethane. Generally, it is required to compress the BOG and then condense it back into liquid form, or directly compress and output it.

The M-type compressor is a reciprocating compressor, and its operating principle is similar to piston motion. The compressor operates by the upward and downward movement of one or more pistons, drawing gas into the compression chamber and compressing it, then discharging it to generate the required pressure.

Hydraulic booster compressors are built in areas without natural gas pipelines. CNG mother stations compress and store natural gas using hydraulic booster compressors, and then CNG trailers transport compressed natural gas at 25 MPa to substations for refueling CNG vehicles.

The D-type horizontal air compressor is a widely used equipment, and its working principle involves compressing air in the cylinder to generate compressed air. This type of compressor typically adopts a horizontal layout for easier installation and maintenance.

M-type CNG compressor adopts four rows of symmetrical balance structure, four rows of crank 90° each other, reciprocating inertia force fully balanced, stable operation of the unit, small vibration. The machine has compact structure and easy maintenance. Especially suitable for the integration of large capacity compressors in large CNG mother station, which requires five stages of compression.

A screw compressor is mainly composed of a pair of parallel, intermeshing rotors (screws) that rotate in opposite directions. This construction makes it the most widely used type of rotary compressor. The screw compressor is a dual-shaft positive displacement rotary compressor, and the number of meshing teeth determines its volumetric efficiency and compression efficiency. In operation, the principle of the screw compressor involves the periodic variation of working volume through the rotation of rotors inside the casing, thereby achieving gas compression. The oil injection amount in this compressor is usually proportional to its rotational speed, allowing for performance adjustment by regulating the oil injection amount.

YZ Series CNG Compressors is suitable for CNG satellite station. The YZ Series CNG Compressor can provide refueling service to vehicles where there is no natural gas pipeline network. It has the characteristics of stable operation, wide application range, low failure rate, safe and reliable, low maintenance cost.