English

English

Large storage tanks are mainly used for peak shaving and distribution in LNG plants and LNG storage terminals. Naide is one of the few companies in China capable of designing and constructing large-scale liquefied natural gas storage tanks. Naide can build tanks with capacities of up to 50,000 m³. We also produce LNG loading/unloading arms and loading b

The small-scale LNG vaporization skid is designed for areas with relatively low natural gas consumption, such as villages or small towns, factories, residential areas, industrial parks, hotels, and similar applications.

An LNG satellite station is a facility for handling LNG transported from LNG storage terminals via tanker trucks or rail. The system consists of LNG storage tanks, vaporizers, and heat control devices. LNG satellite stations help establish a virtual LNG pipeline, enabling the delivery of natural gas to remote areas not served by conventional pipelines. Such stations are typically designed to meet demands of over 1,000 Nm³/h and are equipped with multiple LNG storage tanks and vaporizers.

A standard L-CNG filling station provides CNG refueling and commercial settlement services for CNG vehicles. LNG from tank trucks is unloaded, pressurized, vaporized, and dispensed through the station’s process to fill CNG vehicles with compressed natural gas.

A 1,000,000 m³ liquefaction plant generally refers to a large-scale LNG storage and production facility. Such a plant typically consists of multiple large storage tanks, liquefaction production lines, gas processing equipment, and other auxiliary facilities. The purpose of these facilities is to liquefy natural gas for easier storage, transportation, and sale.

The 500,000 m³ liquefaction plant is a large-scale LNG production facility dedicated to liquefying and storing natural gas. Such plants are typically located near natural gas production sites or transportation hubs to facilitate the delivery of liquefied natural gas to needed locations.

The sled-mounted L-CNG fueling station is an integrated facility that combines natural gas storage, compression, dispensing, and control systems. It typically consists of an LNG storage tank, CNG cylinder bundle, compressor unit, and dispenser, among other main components.

The L-CNG pump skid integrates the plunger pump, instrument cabinet, valves, pipelines, and other components on a single skid. High-pressure vaporizers, EAG vaporizers, water-bath electric heaters, sequential control panels, and other equipment can also be configured in a skid-mounted design. The fully skid-mounted system is ready-to-use upon installation, providing convenience and efficiency.

The 300,000 m³ liquefaction plant is a specialized facility for producing liquefied natural gas (LNG) or liquefied petroleum gas (LPG). This type of plant typically employs advanced process technologies and equipment to convert natural gas or petroleum gas into liquid form through compression and cooling, facilitating storage, transportation, and usage.

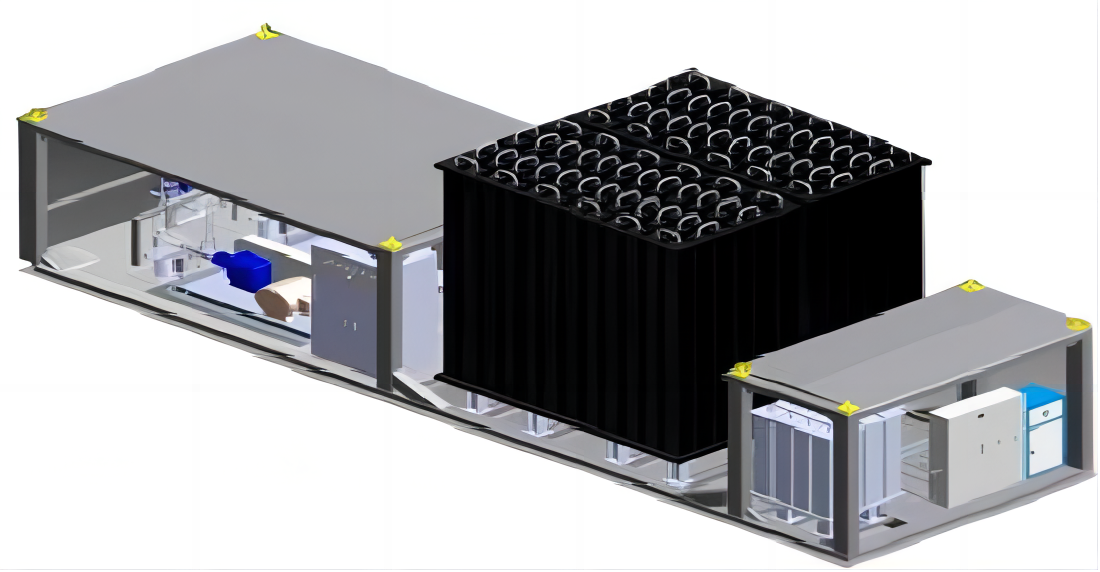

A liquefaction plant is a production facility that processes natural gas by compressing and cooling it until it becomes a liquid. The primary purpose of the plant is to convert natural gas into a form that is easier to store and transport, facilitating long-distance transport and usage.

The L-CNG fueling system is a device used to convert liquefied natural gas (LNG) into compressed natural gas (CNG) through on-site gasification and then refuel CNG vehicles. The main equipment required for this system includes LNG storage tanks, LNG pumps, vaporizers, gas storage cylinders, and CNG dispensers.

LNG can also be used as fuel for barges, replacing diesel, which will reduce carbon emissions, decrease air pollution, and help customers save on fuel costs. LNG fueling stations can be built on vessels floating on rivers to provide bunkering services for barges, or constructed onshore near the riverbank.

It is a small gas supply device, which integrated LNG storage tank, pressure regulators, vaporizers, odorizers, pipelines and other equipment, and supply gas to small users, such as small residential areas, schools, factories, etc.

The LNG loading arm provides a safer means for loading and unloading liquefied natural gas for LNG plants, LNG receiving terminals, LNG stations, and inland LNG fueling stations. It is applicable for LNG tankers, railcars, ISO tank containers, and vessels.

The 100,000 m³ liquefaction plant is a large-scale LNG production facility designed to liquefy natural gas for easier storage, transportation, and sales. Liquefied natural gas is a clean and efficient energy source widely used in power generation, industrial fuel, and other sectors. These plants are typically located near gas production sites or energy consumption centers to meet local LNG demand.

The 100,000 m³ liquefaction plant is a large-scale LNG production facility designed to liquefy natural gas for easier storage, transportation, and sales. Liquefied natural gas is a clean and efficient energy source widely used in power generation, industrial fuel, and other sectors. These plants are typically located near gas production sites or energy consumption centers to meet local LNG demand.

Our prefabricated storage tanks have capacities up to 250 m³, available in vertical or horizontal configurations, and can withstand various working pressures. Options include pearlescent sand or high vacuum insulation. These tanks can be used for different media such as LNG, LIN (liquid nitrogen), LAr (liquid argon), LOx (liquid oxygen), and LCO2 (liquid carbon dioxide).

Endurance high flow LNG dispenser has integrated high performance industrial controlled computer head and high accuracy mass flow meter. All valves and internal parts has passed strict cryogenic test to ensure safe operation. LNG dispenser designed to refuel LNG powered trucks in a safer, easier and more ergonomic way.

Containerized LNG station is the end equipment for filling LNG for the LNG vehicles. Containerized LNG station integrates storage tank, submersible pump, vaporizer, and LNG dispenser in to a containerized skid with metal cofferdam. Except the control system and instrument system which can be installed outside the skid. This station can be save site installation time, cost as well as local civil works.

The LNG gas dispenser is a device used to convert liquefied natural gas (LNG) into compressed natural gas (CNG). First, LNG is extracted from the storage tank and then heated to convert it into a gaseous state. Through appropriate pressure reduction, the high-pressure liquid is transformed into low-pressure gas.

LNG pump skid is integrated with cryogenic pump, vacuum pump pool, vaporizer, vacuum pipeline and valves. It has functions such as unloading, regulating and refueling.

The inner and outer vessels of the product are made of 304 stainless steel, with fully automated CNC welding for the bottle’s exterior, ensuring both aesthetics and reliability. The inner vessel uses fully automated copper-tin brazing, providing full weld penetration and excellent thermal conductivity. Each unit undergoes two static evaporation rate tests, liquid filling tests, airtightness tests, and cylinder pressure tests to ensure product quality.

The 50,000 m³ liquefaction plant is a specialized facility for processing liquefied gases. Its primary task is to liquefy gases such as natural gas and propane to facilitate storage, transportation, and sales. During liquefaction, gases are cooled and compressed into a liquid state, making storage easier and reducing transportation costs.

The 33,000 m³ liquefaction plant is a large-scale facility dedicated to liquefying and storing natural gas or other gases. The plant is typically equipped with advanced liquefaction technologies and equipment to ensure efficient and safe production of liquefied gas.

LNG storage tank is a double wall vacuum insulated tank filled with Perlite or high vacuum multilayer winding. Maximum working pressure of the tank is 12 bar with daily evaporation rate of 0.317%/day under static full status. The tank is integrated with pump unit and is easy to transport through road because of its compact size. It is especially suitable for LNG stations with less filling demand so as to save investment cost as well as land size.