English

English

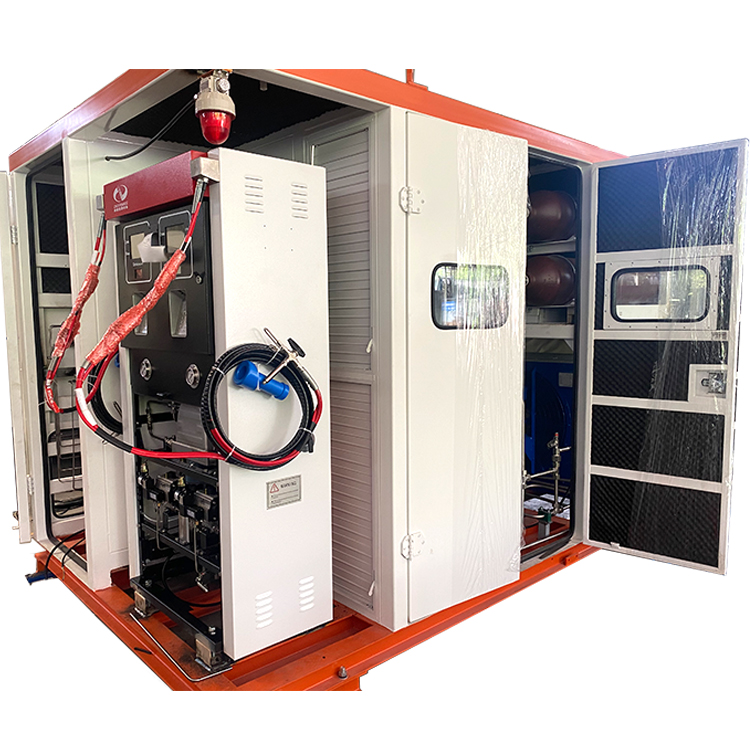

It is a highly integrated CNG filling station. The dipenser, compressor, gas storage cylinder and explosion-proof control cabinet are integrated in one container. The refueling station can be used directly without additional installation.

CNG In a Box system is an innovative solution to build CNG station for you in the shortest period than ever before. Everything in traditional station are prefabricated in a standard ISO container, tested in the factory, delivered to your site and ready to use immediately by simply plug-and-play. Integrated with high speed reciprocate compressor, the station provides you the most cost-efficient solution to build more stations in fastest time and gain the fueling market.

JQ Series high flow CNG dispenser is a forecourt used for refueling natural gas vehicles or NGV in the CNG stations and L-CNG stations for custody transfer like a fuel pump in a Petrol station. We have supplied more than 15,000 CNG fuel dispensers which are running in over 4000 CNG stations in the past 25 years.

CNG Daughter Station is installed where a CNG fill station is desired but there is no natural gas pipeline. Natural gas is brought to the CNG station by mobile storage. A daughter station compressor quickly and efficiently moves the natural gas from the mobile storage to ground storage.

By reducing the finished natural gas from 25 MPa to ~0.8 MPa for regeneration, the regenerated gas is then returned to the compressor inlet. During regeneration, the compressor must be in operation, and the running time must be between 6 to 8 hours.

CNG Storage Cascade Stores CNG at different pressures in groups. After high pressure vaporization, water bath vaporizer, CNG into the priority panel, through automatic distribution, stored in three groups of high, medium and low pressure CNG cylinders. When the distributor refuels the vehicle, the system automatically controls three groups of CNG cylinders to supply gas to the distributor. The process has a high degree of automation, realizing one-click filling, reducing the start-up frequency of the high-pressure pump and reducing the probability of failure.

Using a small-scale scroll compressor as the circulation power source, conducting isobaric closed-loop heating regeneration without the need to release pressure inside the tower, saving resources and protecting the environment, reducing the gas loss of CNG refueling stations, and truly achieving zero emissions. There is no significant pressure change during the regeneration switch, which minimizes the impact on valves and molecular sieves.

JQ Series CNG Filling Post for Tube Trailer is a type of CNG dispenser used for refueling CNG tube trailers, HCV, MCV or LCV transport vehicles in the CNG mother stations. It is designed with high flow rate of up to 75 kg/min.