English

CNG Gas Station

LNG Gas Station

Equipment Maintenance For OilfieldAnd Gas Field

H2 Stations

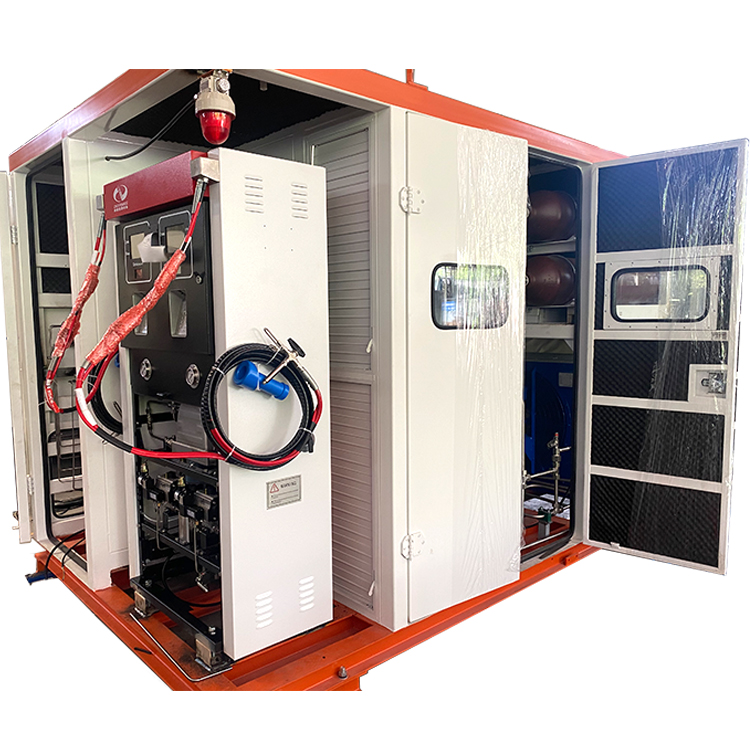

It is a highly integrated CNG filling station. The dipenser, compressor, gas storage cylinder and explosion-proof control cabinet are integrated in one container. The refueling station can be used directly without additional installation.

JQ Series high flow CNG dispenser is a forecourt used for refueling natural gas vehicles or NGV in the CNG stations and L-CNG stations for custody transfer like a fuel pump in a Petrol station. We have supplied more than 15,000 CNG fuel dispensers which are running in over 4000 CNG stations in the past 25 years.

CNG In a Box system is an innovative solution to build CNG station for you in the shortest period than ever before. Everything in traditional station are prefabricated in a standard ISO container, tested in the factory, delivered to your site and ready to use immediately by simply plug-and-play. Integrated with high speed reciprocate compressor, the station provides you the most cost-efficient solution to build more stations in fastest time and gain the fueling market.

Large storage tanks are mainly used for peak shaving and distribution in LNG plants and LNG storage terminals. Naide is one of the few companies in China capable of designing and constructing large-scale liquefied natural gas storage tanks. Naide can build tanks with capacities of up to 50,000 m³. We also produce LNG loading/unloading arms and loading b

The small-scale LNG vaporization skid is designed for areas with relatively low natural gas consumption, such as villages or small towns, factories, residential areas, industrial parks, hotels, and similar applications.

An LNG satellite station is a facility for handling LNG transported from LNG storage terminals via tanker trucks or rail. The system consists of LNG storage tanks, vaporizers, and heat control devices. LNG satellite stations help establish a virtual LNG pipeline, enabling the delivery of natural gas to remote areas not served by conventional pipelines. Such stations are typically designed to meet demands of over 1,000 Nm³/h and are equipped with multiple LNG storage tanks and vaporizers.

A standard L-CNG filling station provides CNG refueling and commercial settlement services for CNG vehicles. LNG from tank trucks is unloaded, pressurized, vaporized, and dispensed through the station’s process to fill CNG vehicles with compressed natural gas.

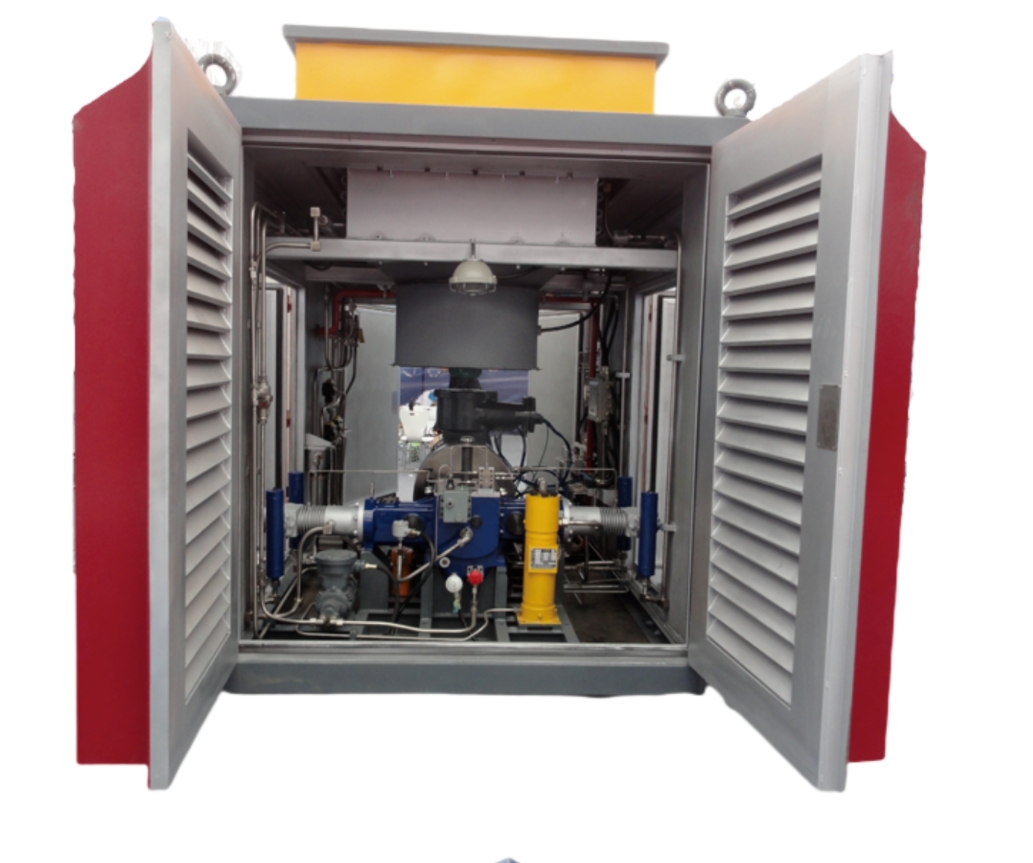

The CNG conventional station compressor adopts a two-column horizontally symmetrical structure, capable of multi-stage compression; the transmission structure uses forced lubrication, and the cylinder adopts a low-oil lubrication method.

CNG skid mounting sub-station compressor drive section adopts two rows of completely horizontal symmetrical structure, cylinder arrangement on both sides, two-stage compression.

The BOG recovery compressor is mainly used for handling low-temperature liquids such as liquefied natural gas (LNG), low-temperature propane, and low-temperature ethane. Generally, it is required to compress the BOG and then condense it back into liquid form, or directly compress and output it.

Natural gas compressors for oil and gas fields are essential equipment used to increase the pressure of produced natural gas for transportation through pipelines or for storage purposes. These compressors play a crucial role in maintaining the flow of natural gas from the wellhead to processing facilities or distribution points.

The isothermal hydrogen compressor is a highly efficient hydrogen compression device that uses mechanical energy to compress hydrogen to the required pressure.

The high-pressure hydrogen charging/discharging column is used for high-pressure hydrogen filling of tube trailers or for supplying hydrogen from tube trailers to compressors for pressurization. It is equipped with a purging interface to reduce impurities of other gases in the system and improve hydrogen purity.

The integrated sled-mounted hydrogen fueling station is an advanced hydrogen refueling facility that integrates hydrogen storage, compression, cooling, and dispensing functions into one unit. It is suitable for small-scale, land-efficient hydrogen station scenarios.

The hydrogen storage well has a structure similar to a CNG storage well. The wellbore extends underground and is composed of segmented well sections.